Yes this is the later radiator model, so shouldn’t be fitted to an early car. But I like standardisation and reliability, and am not bothered too much about originality. I also firmly believe that a car is for driving, not for show grounds. So the ’76 car will get the later cooling system with the header tank instead of the overflow bottle. But the most important reason for this change is that the latter system is the better of the two!

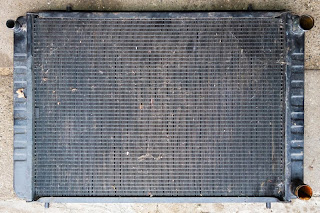

My original plan was to have another alloy radiator fabricated locally, to the same specifications as the alloy radiator that was fabricated locally for my DHC But with such a good spare that seems like a waste of money to me! But before I commit myself I will have to flush and pressure test this one first! Just to be sure.

Also some of the wiring harnesses, especially the main wiring harness, will probably find their way into the ’76 car. Though it doesn’t look like much in the picture above, a first quick check while removing them from the car showed some very unmolested wiring harnesses:

The same can probably be said about the front screen. While removing it, the front surface felt very smooth, so probably only very few (tiny) stone chips. There is also no delamination at the edges worth mentioning. Only a shallow chip in the left hand top corner. Probably there since the screen was fitted to the car at the factory, as it was completely hidden behind the stainless screen surround trim. Again a good clean and a closer inspection will determine whether it will be used or not (I have a few spares as back up though!).

And finally the transmission. The car had only covered 87.173 kilometres, and the overall condition looked like she was pretty well cared for in het past life. So the plan is to use both gearbox and back axle for the ’76 car. I would have loved to put a 3.90:1 ratio back axle under this car. But I only have one spare axle with that ratio. And that will be used to build the new back axle for ‘t Kreng (the one in front in the picture below).

So the ’76 car will also get a 3.45:1 ratio back axle. Just as the DHC. As it stands now that will be the third one from the front., bearing serial number CL 11955. Will see how a bog standard Sprint engine will cope with this ratio. I take comfort in the fact that the Dolomite Sprint also came with this gear ratio.

And I want to keep the gearbox and back axle together for no obvious reason. So this gearbox, bearing serial number CL-130837C will find its way into the ’76 car too.