It's that time of year again! Although my blog might tell a different story, 2013 has been a rather busy Triumph year. Sadly it was completely overshadowed by the death of a very good friend and fellow wedge owner, during the Deutschland Rally in August. Rob you are still missed very much ...

As a result of this work on the various upgrades for 't Kreng have been put on hold for a while. Mainly because most of the work (read fabricating parts) was done to keep his rally car going. And as mentioned earlier I have promised myself not to start on any physical work on 't Kreng until the DHC is completely finished. But since I made that promise another TR7 joined the collection. Resulting in a radical change of plan.

As a result of this work on the various upgrades for 't Kreng have been put on hold for a while. Mainly because most of the work (read fabricating parts) was done to keep his rally car going. And as mentioned earlier I have promised myself not to start on any physical work on 't Kreng until the DHC is completely finished. But since I made that promise another TR7 joined the collection. Resulting in a radical change of plan.

But that doesn't mean I have done nothing on the preparations for the rejuvenation of 't Kreng. Over the past year I have been working every now and then on various adaptations for 't Kreng V2.0, and recently I was able to reap the first rewards of my labours (consisting mostly of taking measurements and making drawings and computer models).

First there is the strengthening plate for the back axle, laser cut from 10 mm aluminium ...

And this piece of 6 mm thick aluminium sheet, which will be turned into a sump guard ...

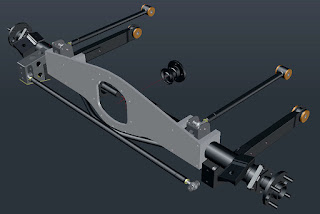

But although these bits are all alloy, they are going to put a few extra kilograms to the car. The good thing being that these items will be mounted low down on the car, so it won't harm the cars centre of gravity. I also acquired a pair of nice and shiny alloy front wheel hubs from Hamilton Motorsport, to shed a little of the extra weight gained. These should knock of approximately three kilo's of the front suspension. But as I won't be fitting them yet I stored them away for the time being, so no pictures yet. And before fitting them I'd like to have them anodised. So a search for a company that can do this is near the top of the to do list.

And this piece of 6 mm thick aluminium sheet, which will be turned into a sump guard ...

But although these bits are all alloy, they are going to put a few extra kilograms to the car. The good thing being that these items will be mounted low down on the car, so it won't harm the cars centre of gravity. I also acquired a pair of nice and shiny alloy front wheel hubs from Hamilton Motorsport, to shed a little of the extra weight gained. These should knock of approximately three kilo's of the front suspension. But as I won't be fitting them yet I stored them away for the time being, so no pictures yet. And before fitting them I'd like to have them anodised. So a search for a company that can do this is near the top of the to do list.

Then there was the very long struggle to get the DHC ready for Club Triumph's 10th anniversary edition of the 10 Countries Run. But in the end I got her to the start and she performed faultless during the entire run. What more could I wish for !? And although I didn't use the cars as often as I would have wanted, they both saw a fair amount of action. With the best being these three events organized by Club Triumph;

- Taith-o-Amgylch-Cymru (or a Tour of Wales)

- The international AutoEcosse

- The 10 Countries Run (in two parts)

I already mentioned that my TR7 plans have been changed. This is what the plans are as I see them now at the end of 2013;

The DHC: that needs a few finishing touches. The dashboard illumination needs upgrading. Despite fitting new bulbs one side is very badly lit. It looks like one or two of the bulbs are not working. Maybe need to fit another circuit to the back of the instrument cluster. Then there is the problem with the fuel gauge. Still have to look through my spares to find another low fuel delay unit. And last I am currently waiting for a friend to make me some nice and shiny alloy wheel centres for the DHC's new wheels. The finished product should look like this ...

And as a future project I will replace the SU carburettors with an original FI setup I have lying around. But I will replace the single throttle body, ECU and injectors for modern parts.

And as a future project I will replace the SU carburettors with an original FI setup I have lying around. But I will replace the single throttle body, ECU and injectors for modern parts.

't Kreng: Initial plan had been to dismantle her as soon as the DHC was completely ready and reliable. But even before I acquired the '76 FHC that plan had been abandoned in favour of a "rolling" approach. So I will tackle the various jobs one by one without taking the car of the road for a longer period. Added bonus, especially with the suspension upgrades, is that it can be controlled much better. There is time in between jobs to drive the car and evaluate how the handling reacts to a modification. The rest of the plans for her are unchanged, safe for the paint job I had in mind ...

'76 FHC: As already mentioned :-). Hopefully the body man will be able to inspect the car within the next few weeks. So I can start to plan the various jobs that need to be done.

And in between I also managed to go back to Süd Tirol in a boring grey Euro-box for a two week walking and photography holiday. As a few pictures tell so much more than lots of words, some of the high lights:

I'd like to wish you all the best for 2014. See you next year.