Understeer is when you hit the wall with the front of the car. Oversteer is when you hit the wall with the rear of the car. Horsepower is how fast you hit the wall. Torque is how far you take the wall with you ... Or ramblings on three originally Dutch TR7's (a 1976 FHC, a 1980 DHC and a 1981 Sprint powered FHC), including the work done to them and their (ab)use all over Europe. With some of my other passions thrown in from time to time ...

Sunday 31 January 2021

Sunday Walks in January

Sunday 17 January 2021

FHC resto nr. 120; Rear wing blanking plate and radiator

After finishing the car’s striping, fitting the

two rear wing blanking plates (ZKC1454) prepared

2 years ago, should have been easy. Well the driver’s side was!

The opposite side decided to put up a fight. However hard I tried, the push-on spire nut (ZKC2539) refused to seat properly against the inside of the wing. And after the second attempt I decided to have a closer look at the blanking plate. Should have done that when I selected a pair of blanking plates for refurbishing and use on the car. The only selection criteria at the time were the outside looks. I should have paid a little more attention to the (hidden from view) moulded plastic mounting pins at the back!

Clearly visible is the ridge near the base of the mounting pin. This is almost certainly caused by the blanking plate being removed a few times in the past. And this ridge turned out to be the cause for my problem. It prevented the spire nut from seating correctly, leaving it almost 1 millimetre free of the sheet metal.

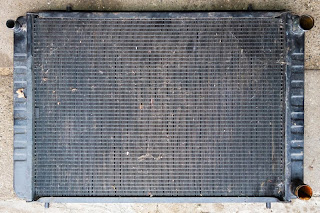

And after returning home from the shed I decided to spent the remaining part of the afternoon with a first inspection of the radiator I removed from the parts car. To prevent it from drying out I had stored it in the cellar, filled with water. And after emptying it, I transferred it to the bathroom for an external and first internal cleaning session.

Looking pretty good overall, though it will need a bit of satin black paint and some rust converter in certain areas. And I found this tag, which might explain its condition. Presuming the tag shows the manufacturing date, this radiator is clearly not factory fitted, but an aftermarket replacement.

Remained the inside. Rather difficult to capture with a camera. There are still clear signs of a rusty deposition, especially at the bottom of the radiator (first picture) where a rusty coloured sludge sat when I removed the radiator from the car. But all visible pipes from the radiators core look free and clean.

Sunday 10 January 2021

FHC resto nr. 119; Parts donor's yields

Yes this is the later radiator model, so shouldn’t be fitted to an early car. But I like standardisation and reliability, and am not bothered too much about originality. I also firmly believe that a car is for driving, not for show grounds. So the ’76 car will get the later cooling system with the header tank instead of the overflow bottle. But the most important reason for this change is that the latter system is the better of the two!

My original plan was to have another alloy radiator fabricated locally, to the same specifications as the alloy radiator that was fabricated locally for my DHC But with such a good spare that seems like a waste of money to me! But before I commit myself I will have to flush and pressure test this one first! Just to be sure.

Also some of the wiring harnesses, especially the main wiring harness, will probably find their way into the ’76 car. Though it doesn’t look like much in the picture above, a first quick check while removing them from the car showed some very unmolested wiring harnesses:

The same can probably be said about the front screen. While removing it, the front surface felt very smooth, so probably only very few (tiny) stone chips. There is also no delamination at the edges worth mentioning. Only a shallow chip in the left hand top corner. Probably there since the screen was fitted to the car at the factory, as it was completely hidden behind the stainless screen surround trim. Again a good clean and a closer inspection will determine whether it will be used or not (I have a few spares as back up though!).

And finally the transmission. The car had only covered 87.173 kilometres, and the overall condition looked like she was pretty well cared for in het past life. So the plan is to use both gearbox and back axle for the ’76 car. I would have loved to put a 3.90:1 ratio back axle under this car. But I only have one spare axle with that ratio. And that will be used to build the new back axle for ‘t Kreng (the one in front in the picture below).

So the ’76 car will also get a 3.45:1 ratio back axle. Just as the DHC. As it stands now that will be the third one from the front., bearing serial number CL 11955. Will see how a bog standard Sprint engine will cope with this ratio. I take comfort in the fact that the Dolomite Sprint also came with this gear ratio.

And I want to keep the gearbox and back axle together for no obvious reason. So this gearbox, bearing serial number CL-130837C will find its way into the ’76 car too.

Saturday 9 January 2021

Parts donor part 5

The same could be said of refitting the back axle. I choose to first fit the four links to the body and add the axle to the lower links first, with the aid of the trolley jack. While doing this the upper links were tied up against the tank, to prevent them from intervening at inappropriate moments! Only the last bolt put up a bit of a fight to get in place. Which it lost within a few minutes.

With the back axle in place it was time for the final part of this chapter. Removal of the engine and gearbox. Which meant the rear of the car had to be jacked up as high as the trolley jack would go. Then put the axle stands in place (including extra stands under the back axle to prevent from being in the way. This also would free the trolley jack to be used under the gearbox.

For the actual removal of the engine I had borrowed an engine crane from a friend. Sadly though out the previous user, who had borrowed it from him, hadn’t mentioned there was something wrong with it, when he returned it. It turned out to be low on hydraulic oil. Resulting in the lifting arm not even getting level. Let alone reaching enough height to swing the engine out over the nose panel.

Of course that was the moment for the gear box to have a mind of its own. While investigating why the lift wouldn’t go any higher, the gearbox managed to slip of the trolley jack in an unguarded moment. Leaving the assembly on its side at a rather awkward angle in the engine bay, with hardly any room to manoeuvre. Took us about half an hour to get it back in its original position with some sturdy wooden blocks supporting the gearbox. After which there was nothing we could do but pack up the tools, make a to-do-list and head for home. And to return in the following year!

And on the first Saturday of 2021 we returned to the shed, armed with hydraulic oil and a small oil pump. With the oil level topped up, we had a fully functional crane again. The arm’s reach again was high enough to remove the engine from the engine bay.

And yes the chain’s shackles were too long to get the engines angle spot on. But we were able to get the engine over the nose panel and lift the gearbox out of the engine bay by hand. Almost as easy as it sounds. And no damage to the cars bodywork!

Last job, before moving the car on to its final destination, was removing the gearbox, and the clutch cover and plate from the engine. And with that task done, we came to the final task in my “ownership”, loading her onto the trailer and moving her off to a friend, for the next chapter in her life! His plan is to use this overall very solid body shell, to re-shell his current car. But that chapter won’t be written by me. That’s up to the new owner, if he feels up to it!