(Or tackling the last job from the aftermath of the 2011 edition of the 10CR ...)

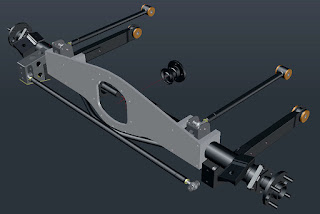

I finally got round to changing the damaged front anti roll bar. The powder coating on this was badly damaged, which in its own might not be enough to justify the work involved. But as the tracking had suffered slightly from the accident (so had to be reset anyway) and I didn't want to be reminded of the incident in years to come, the decision was easy! (this is how it looked once removed).

The actual job of removing and refitting the front anti roll bar is pretty straightforward. But in my case I adapted it all a bit with a stiffening plate and a homemade anti-dive-kit, making removal and refitting a little bit tricky. Also putting the clamps and the retaining washers over the freshly coated anti-roll-bar without damaging the coating, was a bit of a nightmare which took much longer than expected.

The actual job of removing and refitting the front anti roll bar is pretty straightforward. But in my case I adapted it all a bit with a stiffening plate and a homemade anti-dive-kit, making removal and refitting a little bit tricky. Also putting the clamps and the retaining washers over the freshly coated anti-roll-bar without damaging the coating, was a bit of a nightmare which took much longer than expected.

But the biggest problem yesterday was the weather. First the temperatures rose to a very humid 30ºC before plummeting down 10ºC during a fierce thunderstorm, reaching well over 30ºC again soon after that. Needless to say I needed lots of breaks to wipe the sweat from my eyes and to refill my body's fluid levels. All those breaks off course meant lots of small things were forgotten, so more time wasted to rectify them ...

As said the actual removal and refitting of the anti-roll-bar is pretty straight forward, as long as you do it correctly. Most people jack up the car, put axle-stands to support the body and remove the wheels. After which they start the struggle to remove and refit the anti-roll-bar's ends from the track control arms. And there's only one reason for this struggle. Due to the suspension being at full droop there's a fair amount of tension on the anti-roll-bar. You can try to get the ends closer together with ratchet straps or even hydraulic pull cylinders, but it is far easier to use two trolley-jacks.

After securing the front of the car with axle-stands and removing the wheels, the trolley jacks are placed underneath both the suspension struts, at a right angle with the car's axis. Now you jack up both ends of the car till you have maximum load on the suspension, so with the body just free from the axle-stands. This results in the track-control-arms being almost horizontal and as such the anti-roll-bar's mounting points sit further apart, making removal and refitting of the anti-roll bar a manual job which doesn't need much strength. Only problem you might encounter is not enough room to fit the rear bushes, retaining washers and nuts. But that depends on the jack's position and the shape of the lifting plateau. In my case no problems there.

Remains a check of the wheels alignment, hopefully I will be able to make an appointment to have that checked soon ...

As said the actual removal and refitting of the anti-roll-bar is pretty straight forward, as long as you do it correctly. Most people jack up the car, put axle-stands to support the body and remove the wheels. After which they start the struggle to remove and refit the anti-roll-bar's ends from the track control arms. And there's only one reason for this struggle. Due to the suspension being at full droop there's a fair amount of tension on the anti-roll-bar. You can try to get the ends closer together with ratchet straps or even hydraulic pull cylinders, but it is far easier to use two trolley-jacks.

After securing the front of the car with axle-stands and removing the wheels, the trolley jacks are placed underneath both the suspension struts, at a right angle with the car's axis. Now you jack up both ends of the car till you have maximum load on the suspension, so with the body just free from the axle-stands. This results in the track-control-arms being almost horizontal and as such the anti-roll-bar's mounting points sit further apart, making removal and refitting of the anti-roll bar a manual job which doesn't need much strength. Only problem you might encounter is not enough room to fit the rear bushes, retaining washers and nuts. But that depends on the jack's position and the shape of the lifting plateau. In my case no problems there.

Remains a check of the wheels alignment, hopefully I will be able to make an appointment to have that checked soon ...